![]() WhatsApp: +8618615261626

WhatsApp: +8618615261626

![]() Wechat: +86 18615261626

Wechat: +86 18615261626

![]() Mail: info@tekaicnc-laser.com

Mail: info@tekaicnc-laser.com

![]() Skype: info@tekaicnc-laser.com

Skype: info@tekaicnc-laser.com

Model: TEJ1530F fiber laser cutting machine

Brand:Tekai

Working area: 1500x3000mm

CNC or not: CNC

Original: CN(Origin)

Delivery Time: 20-25 working Days

Certificatres: CE, FDA, ISO

Customized: Accept

Voltage: AC 220V/380V, 1P/3P, 50HZ/60HZ

Supply Ability: 90 Sets/Month

Packing size: 3940X2280X1600mm

Payment Terms: T/T(Telegraphic Transfer), Mastercard, e-Checking

#High speed, high precision, high efficiency and low cost

#Easy on operation, fiber optical path, without tediously adjustment on optical path

#Compact structure, good sealing, strongly adaptable to changes in the environment.

#With the perfect automatic nesting system which can save time, save the materials, the sheet utilization ratio up to 95%

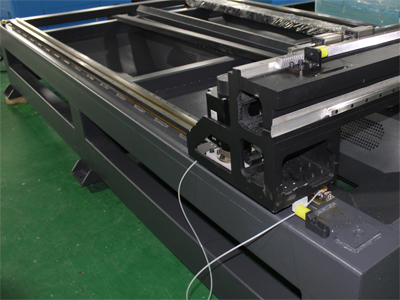

#Moving crossbeam, imported high precision racks and linear guide rail, stable transmission, high precision.

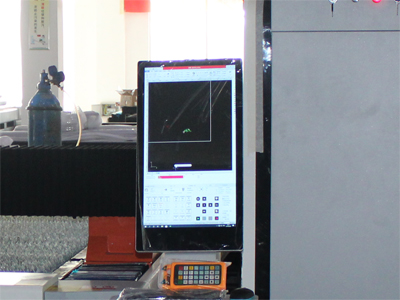

#Using professional and powerful Shanghai Cypcut fiber cutting controlling system that based on Windows operating system, with good

Human Machine Interaction and easy operation.

#Laser is produced without gas and it could use air to cut sheet metal

#Machine frame, crossbeam and worktable adopt integral welding structure. With stress relief annealing and vibration stress relief treatment,

it can completely eliminate the welding and processing stress, maintaining high strength and precision, keeping the normal use of 20 years without deformation

Cypcut operating system

Shanghai Cypcut operating system ,advanced technology,suitable for kinds of material cutting.

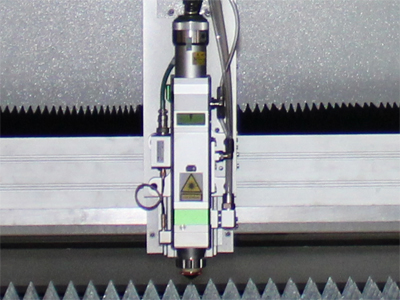

Raytools cutting head,Auto- focus function

X、Y axis: Japanese YASKAWA 850W Servo motors and drivers Our X Y aixs structure

increases machine speed and precision and more stable for machine working

Z axis: Japanese Panasonic 400W Servo motor and driver

3rd Generation Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its

strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as

good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Laser Source

Origion Raycus laser source

Optional:IPG

France Schneider electrical part

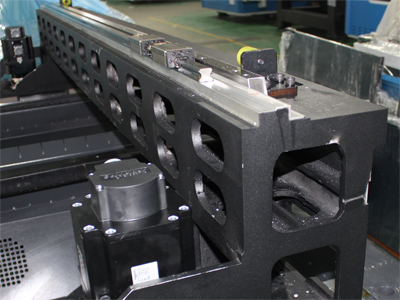

Tube Welding Heavy Work Bed

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes.

Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and

stability of the guide rail so as to effectively avoid the deformation of the bed.High strength, stability, tensile strength, ensuring 20

years of use without distortion;

Thickness of rectangular pipe wall is 10mm and weights 3500 kg.

Professional cooling systems, refrigeration temperatures are shown in table, the water temperature in excess of the prescribed temperature

refrigeration unit automatically when cooling, refrigeration unit automatically stops when the water temperature below the specified temperature refrigeration.

# Working area:1500x3000mm

# Laser generator 2000w, Raycus brand

# Raytools brand Cutting head with auto following system

# Cypcut controller system with wireless hand-wheel

# Taiwain Hiwin guide rails 30mm

# Taiwan APEX gear and rack

# Industrial water chiller

# XY axis Japanese Yaskawa servo motor 850w

# Z axis Yaskawa 400w servo motor

# Japanese SMC Airtac pneumatic element

# French Motovario reducer

# French Schneider Electronic Components

# Automatic lubrication system

# Computer with contorl system and design system installed well.

Option parts:

# Bigger power laser recourse for cutting more thickness

# Up and down exchange platform

# Full encirclement

# Rotary for metal tube cutting

| Modle | TEJ1530F Fiber laser cutting machine |

| Working area | 1500x3000mm |

| X/Y axis Repeated Position | ±0.02mm |

| Laser Generator | Wuhan-Raycus or Germany-IPG |

| Control system | Cypcut contorl system |

| Transmission | Gear+rails |

| Laser head | Raytools automatic cutting head |

| Motor and driver | Yaskawa servo motor |

| Rotary pipe cutting | Option parts |

| Table structure | Sawtoolth |

| Working voltage | 380V, 50HZ/60HZ |

| Moving speed | 80M/Min |

| Gross weight | 3500KG |

| Net weight | 3000KG |

| Machine size | 4800*2600*1860mm |

| Cutting thickness | It ups to the materials and power |

| Application materials | Metal sheetIron/CS/SS/Aluminum/Copper and all kinds metal |

Applicable materials:

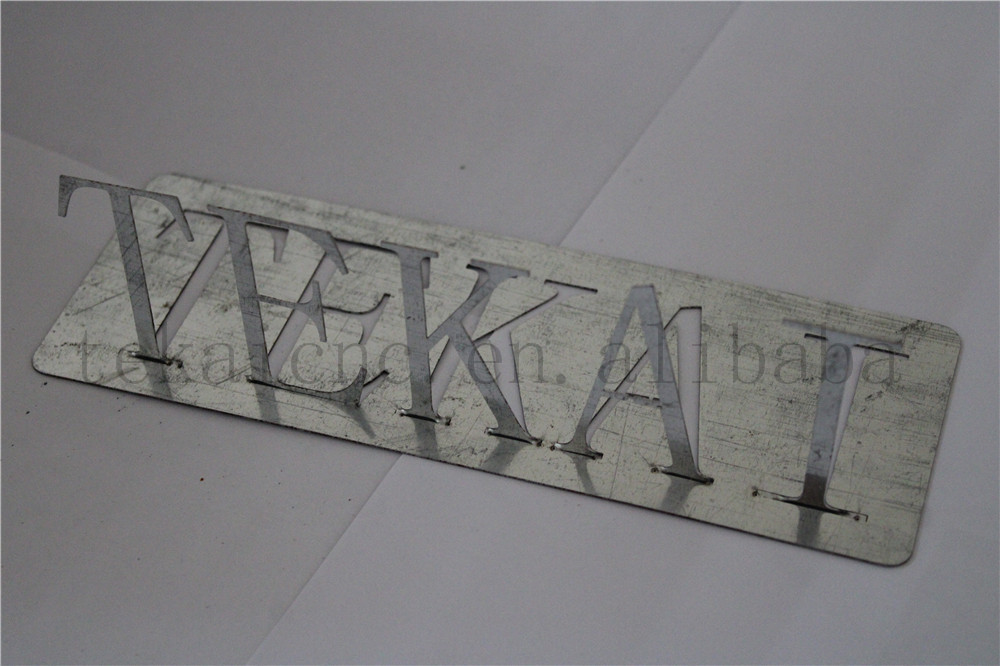

Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting like stainless steel sheet, mild steel plate

carbon steel sheet, alloy steel plate, spring steel sheet, iron plate, galvanized iron, galvanized sheet, aluminum plate, copper

sheet, brass sheet, bronze plate, gold plate, silver plate, titanium plate, metal sheet, metal plate, etc.

Applicable Industries:

Fiber Laser Cutting Machines are widely used in manufacture billboard, advertising, signs, signage, metal letters, LED letters,

kitchen ware, advertising letters, sheet metal processing, metals components and parts, ironware, chassis, racks & cabinets

processing, metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, glasses frame, electronic parts,

nameplates, refrigeration machinery, agricultural machinery, food machinery, kitchen stainless steel countertops, aerospace,

railroad locomotive, auto parts manufacturing, car body processing, medical equipment, smart home, home appliances, kitchen

equipment, fitness equipment, machinery manufacturing, sheet metal processing. etc.

CNC HS code: 8465990000

Laser HS code: 8456110090

Oscillating knife cutting machine:8453800000

© Copyright - 2010-2023 : All Rights Reserved.

Hot Products - Sitemap - AMP Mobile