The water cycle vacuum pump is engraving machine vacuum adsorption table necessary equipment, the use of vortex air pump suction to fix the cut, so that the cut in the cutting process is not offset, to ensure that the height of cutting accuracy.

CNC router machine opener used water cycle vacuum pump power models are generally 4.0KW, 5.5KW, 7.5KW, etc., different power vacuum adsorption strength is also different.

Water cycle vacuum adsorption pump main components:

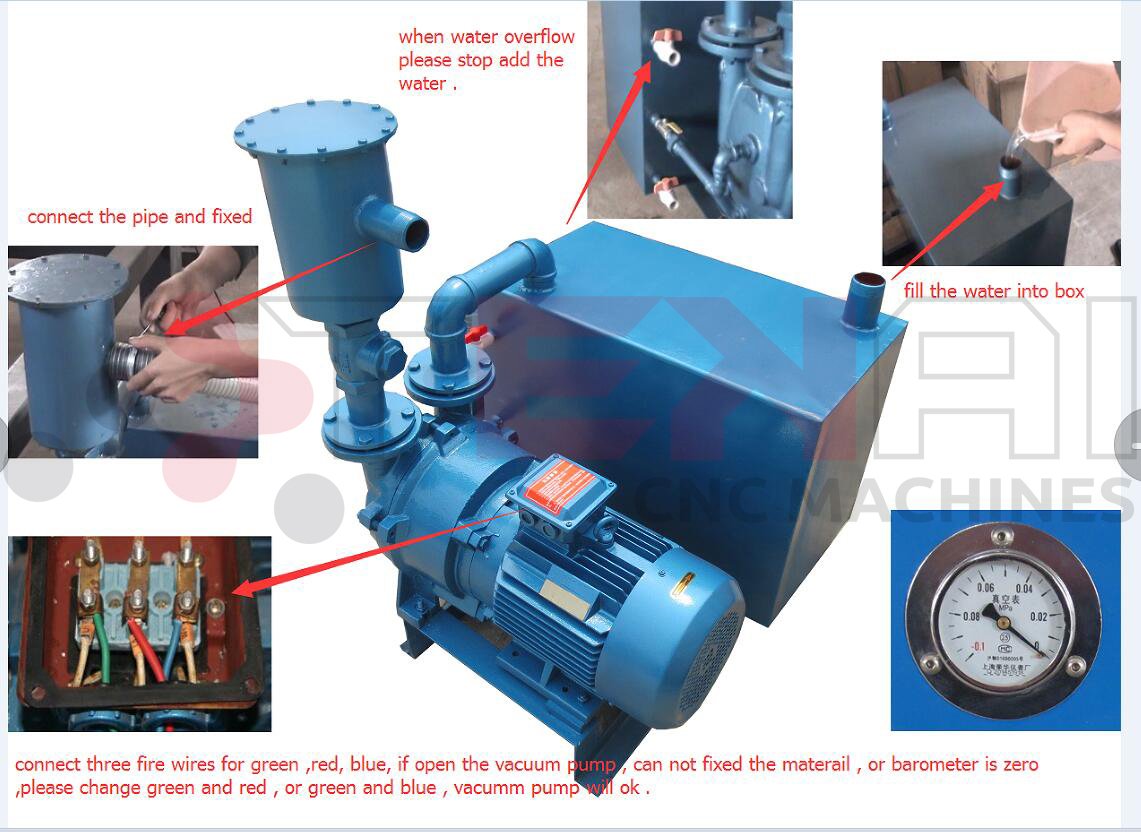

1. Suction port: connect the adsorption pipe of woodworking engraving machine.

2. Dust cover: prevent wood chips and other sundries into the pump.

3. Check valve: stop the pump to prevent the water back into the equipment.

4. Water inlet pipe: inject working liquid into the pump to produce vacuum.

5. Water inlet valve: control the flow of working liquid, before starting the valve must be completely opened, and ensure that the water has entered the pump, can start the vacuum pump.

6. Drainage outlet: After about 10 days of use, drain the working liquid in the water tank and replace it with clean softened water.

7. Exhaust port: the gas generated in the adsorption process is discharged into the atmosphere through the exhaust port. The exhaust port can not be blocked, can not be connected with more than two meters of pipeline, can not be connected with the diameter of less than 5CM pipeline, otherwise it is easy to overload, damage the motor.

8. Upper water level: add water to the water tank until the upper water level drip out, and regularly add water before starting the vacuum pump every day to ensure that there is sufficient working liquid (water) in the water tank.

9. Water tank: holding working liquid (water).

Every time you start the vacuum pump, make sure there is working fluid in the vacuum pump! And the working level should reach above the motor wheel shaft!

1. The suction port is connected with the engraving machine adsorption pipeline, and is strictly sealed to prevent leakage.

2. The first start, with a screwdriver toggle motor fan, to ensure that the impeller is not stuck.

3. Connect the motor power supply, and adjust the direction of operation in accordance with the standard.

4. Water into the water tank, until the upper water mouth drip water.

5. Open the water injection valve into the pump, and wait for three minutes to ensure that the working liquid flows into the pump.

6. Start the motor, the vacuum pump starts to work, adsorption table to produce adsorption effect. Test adsorption strength.

7. Install motor overload protector to prevent motor overload from burning !!!! (Special attention)

Water cycle vacuum pump maintenance

In the process of using the water cycle vacuum pump, if it is found that the suction is insufficient and the sound of the motor becomes light, please stop immediately for inspection

1. Patiently check whether the water level of the water tank is higher than two thirds of the height of the vacuum pump head. If it is too low, please add water immediately.

2. If the water level of the water tank is high enough, please check whether the water inlet pipe between the pump heads of the water tank is blocked, resulting in insufficient water supply.

3. After cleaning and replenishing the equipment, be sure to plug the air inlet after starting the equipment, and control the air intake to let enough water flow into the pump body and produce enough vacuum degree.

4. Clean the water tank, water inlet pipe and change water within 150 days after vacuum pump is used. Please close the water inlet valve of the water tank and empty the water in the water inlet pipe. If it is not used for a long time, please thoroughly control the water inside the water pipe and the pump head to prevent rust and affect operation.

5. If it is not used for a long time, if it is found that the motor cannot run after power-on, it is recommended to use pipe pliers to rotate the fan blade shaft after force, so that the rust point of the pump head is loosened, then it can be used normally.

Common problems of water circulation vacuum pump

1. Vacuum pump does not vacuum.

Main reason: the working liquid did not enter the pump cavity, did not form a water ring or suction line leakage.

2. The motor does not turn when the vacuum pump is first started.

Main reason: Because the clearance between the impeller and the disk is very small, the cast iron parts are oxidized, and the impeller outlet is stuck. The main solution is to open the fan cover of the rear end of the motor, tap the rear axle head of the motor with a hammer, and then rotate the motor blade by hand. After confirming the rotation, install the fan cover and start the motor.

3. Vacuum pump suction is insufficient.

Main reason: Is insufficient working fluid, check the water inlet pipe; The suction pipe leaks. Check the sealing performance of the suction pipe. The working liquid has not been replaced for a long time, and a large amount of wood dust entering the working liquid affects the quality of the working liquid, so it is necessary to pay attention to keep the working liquid clean water.

4. Vacuum pump noise.

Main reason: Is that all the valves in the suction pipe are closed. The vacuum pump pumping reaches its limit, and the cavitation erosion sound is generated. The noise of the inlet pipe valve will disappear when it is opened.

Start from the details, according to the requirements of the standard operation and use, the machine can be used for a long time.

© Copyright - 2010-2023 : All Rights Reserved.

Hot Products - Sitemap - AMP Mobile